Product

●

Category:

Toggle type Injection Molding Machine-90T~180T

●

GUANGDE have got a professional team for most of exact product application to do customized solutions so that create maximum values for our clients.

Product consultationProduct description

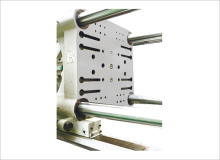

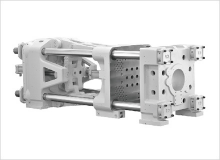

CLAMPING UNIT

● Clamping mechanism guarantees best mold ftting.

● Uniform clamping force distribution increases mold service life and reduces flash in plastic product.

● High speed clamping achieves higher productivity;

● Computerized control for steady and precisely controlled injection pressure increases both machine and molds' service life.

● FEM analysis of mechanical behavior increases platens performance by 15%.

● Tie bar oriented shaping surface decreases stress by allowing force to evenly distribute and thus increases service life.

● The nuts with oriented shape prevent stress concentration on tie bar.

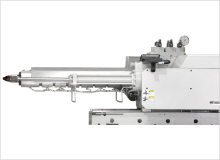

INJECTION UNIT

● Within 0.1 second response rate, the controller can achieve the repeatability up to 0.1% accurancy.

● Digital back pressure can be controlled at high accuracy inside the machine controller.

● High-torque hydraulic motor enables good plasticizing and molding for different resins.

● Steady double cylinder injection unit with high level of precision.

● Screw auger is corrosion-resistant and variations to match different resins are available.

● Hot rolling type steel by heat treatment with excellent strength and hardness.

● Quench hardened with great strength.

● Rust and corrosion proof by at-rust treatment.

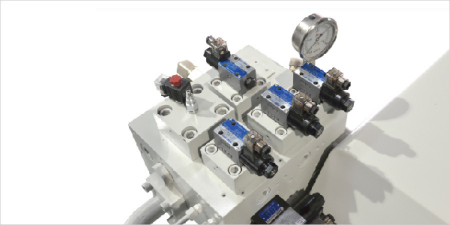

HYDRAULIC UNIT

● Servo driven, energy savings 30% to 70% less power consumes compared to the previous variable displacement pump system.

● Logical hydraulic manifold design, for ultra fast response.

● All machine design for easy repair and maintenance.

ELECTRIC UNIT

● Completely software calibration function.

● Temperature accuracy 0.1°C , analog input (position) accuracy 0.01mm.

● Input:48 points; output 48 points (6 DC points or AC points).

● Multi-language support 2 languages(standard) can be upgrade to 10 languages(optional).

● Use usb interface,all programs are updated by usb.

EMACHINE FUNCTIONS

Injection Unit

Function Description Standard Option

Standard nitrided screw ●

Other made for special resins ◎

Preumatic or hydraulic shut off nozzle ◎

Twin injection cyliners structure ●

Carriage movement by linear transducer ◎

Screw RPM display in controller ●

High torgue plasticising hydraulic motor ●

Digital back pressure control ●

Barrel feeding zone temperture motitor ◎

Purge Guard ◎

Barrel heating with insulation protection ◎

Heating barrel supporter (above 600T) ●

Resin loading perform ◎

Automatic lubrication system ◎

Ceramic heater bands ◎

Infrared heater bands ◎

Simutaneous plasticising by Servo motor ◎

Clamping Unit

Function Description Standard Option

Screw hole mold platen ◎

T-slot mold platen ●

Mechanical,electric and clamping unit ●

Automatic mold height adjustment by hydraulic motor ●

All machine movements by liner transducers ●

Adjustable mold platen supporting device ●

Moving platen protectedby high rigid linear guardrod ●

Clamping zone with top cover (CE Standard) ◎

Servo driven automatic safety door (Operator side) ◎

Euromap 12 or 67 robot interfaces ◎

Extended guard doors for extra UPVC fitting cyliners ◎

Fast & Easy plugs water regulators for molds ●

Air clast device ◎

Mold water regulators with tempature and flow control ◎

Hydraulic Unit

Function Description Standard Option

Servo motor system ●

Variable pump ◎

Increase pump motor capacity ◎

Sequentisl injection system ◎

High injection speed by accumulator ◎

Injection servo valve ◎

Hydraulic oil level alarm ◎

Regeration clamping system ●

Ejector on fly ◎

Simotaneous plasticising ◎

Electric Unit

Function Description Standard Option

Taiwan Dizhou controller ●

European KEBA controller ◎

Constantly monitor of machine function ●

Monitoring for production data ●

Three-color warning lamp ●

Servo motor overload protection ●

Emergency stop for both guard doors ●

Servo power system transformer ◎

Screw cold start-up prevention ●

Safety relay monitoring ●

Heating solid relay control ●

Computer network central control system ●

Hot runner control and interface ◎

Real time energy consumption monitor ◎

Constantly monitor of clamping force ●

Other

Function Description Standard Option

Special color ◎

Higher machine base ◎

Robot ◎

Tailor made molded product output bin ◎

Other related products

●

Leave us a message

●

* is required! You can ask any questions in the company, including products. Please fill in the correct contact information so that we can reply to you in time!